In axial piston pumps, the pistons reciprocate parallel to the axis of rotation of the cylinder block. The simplest type of axial piston pump is the swash plate in-line design.

The cylinder block in this pump is turned by the drive shaft. Pistons fitted to bores in the cylinder block are connected through piston shoes and a shoe plate, so that the shoes bear against an angled swash plate causing the pistons to reciprocate. The ports are arranged in the valve plate so that the pistons pass the inlet as they are pulled out and pass the outlet as they are pulled back in.

The displacement of axial piston pumps is determined by the size and number of pistons, as well as the stroke length which is determined by the size and number of pistons, as well as the stroke length which is determined by the angle of the swash plate.

Variable Displacement Pumps are used in closed loop systems either as a single or tandem pump. Oil is circulated by the pump to the motor and then returned directly back to the pump. A charge supply is used to supplement the closed loop system with oil. The charge supply may be supplied by an internal charge pump (standard) or an external source.

Applications for Eaton Pumps

Eaton pumps have a variety of applications in industry. Among them are:

- Joysticks or Potentiometers

- Programmable logic Controllers

- Torque motor servo valve current drivers

- Harvesting equipment

- Forestry Equipment

- Construction

- Turf Care

- Industrial Equipment

- Paving

Longevity of Eaton Hydrostatic Transmissions is dependent on the proper selection and installation of components.

Proper operation depends on the following components:

- Variable displacement pump

- Fixed or Variable Displacement motor

- Reservoir

- Filter

- Charge Pump Inlet Line

- Pump and Motor Case Drain Lines

- High Pressure Lines

- Heat exchanger

- Heat exchanger bypass valve

- Reservoir return line

Hydraulic fluid recommendations for Eaton Pumps

Proper selection of fluids/oils assures that the system operates optimally and and also ensures an appropriate life-span for the equipment in question.

Viscosity and Temperature

One of the most important characteristics to look out for when choosing hydraulic fluid is its viscosity. The fluid must be thin enough to flow easily, yet thick enough to maintain lubrication and smooth working of the hydraulic system as it reaches operating temperature.

Cleanliness

The majority of failures in hydraulic systems is as a result of dirty or contaminated hydraulic fluid. Appropriate filters must be installed at the outset in order to eliminate any impurities from the hydraulic fluid.

The condition of the hydraulic fluid is directly proportional to the performance of the system. Proper viscosity, cleanliness and water content and levels of any additives are essential for the optimal performance of the equipment.

Some considerations

- When choosing hydraulic fluid, equal consideration must be given to all the component s of the hydraulic system.

- The viscosity limitations have to meet the most stringent component requirements.

- Take fluid level reading when the system is cold. Ensure that fluid level does not run low.

View the full Eaton Brochure here

Eaton and Vickers

Vickers Piston Pumps: Series PVE, PVH, PVQ

Series TA19

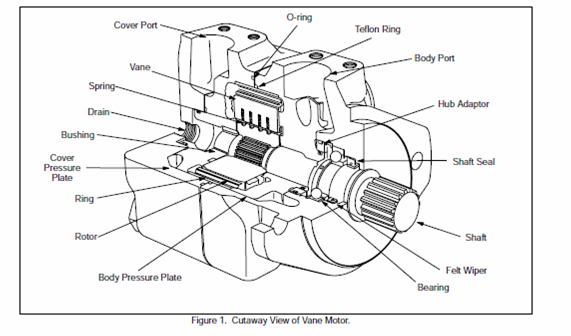

Vickers Vane Pumps & Motors 25M, 35M, 45M, 50M Series 20 Design Cartridge Kits

Remanufactured Products

I order to combat the steady flow of hydraulic products which have reached the market with the claims that the product "Will Fit" and are "As good as new" Eaton and Vickers have embarked on the production of remanufactured products.

Eaton and Vickers have labeled these products as Eaton Genuine Remanufactured Parts because the parts are not to Eatons original specifications. Because nobody knows Eaton parts better than Eaton it is better to get the genuine remanufacture parts rather than the "will fit" category.

Problems that can occur with hydraulic pumps:

- Aeration -The presence of air bubbles within the systems hydraulic fluid

- Cavitation - Happens when restricted fluid flow creates voids that implode and cause damage to surface material.

- Contamination - Foreign material present in the fluid.

- Excessive heat - which in turn can trigger any of the aforementioned.

- Over-pressurisation - Excessive pressure can lead to premature pump failure

- Improper fluid - can cause excessive wear and tear, eventually leading to pump seizure.

The benefits of installing Eaton and Vickers genuine remanufactured parts:

- Eliminate the guesswork

- Warranty

- Repair

- Troubleshooting

- Application engineering

- Training

Local Support

- Fast response

- Eaton certified

- Vanway Linear Crusher

- Parker Hannifin Hydraulics

- Bosch Rexroth Hydraulics

- Poclain Hydraulics

- Nachi Hydraulics

- Kawasaki Hydraulics

- Eaton Pumps

- Parker Hydraulics

Get in Touch!

Get in touch with our hydraulics specialists or call +27 11 882 8104